-

Contact: Andrew Price-Greenow

-

andrew.greenow@kgd.co.uk

-

01432 374374

-

www.kgd.co.uk

-

Netherwood Road

Rotherwas Industrial Estate

Hereford

HR2 6JU

Herefordshire

- Size

- SME

- Direct employees

- 90

- Turnover (reported)

- £10,000,000

- Regional Markets

- Asia, Africa, Australia, Europe, North America, South America

- Nuclear Contracting Tiers

- Tier 3: Original Equipment Manufacturing Organisations

Tier 4: Sub-component Suppliers/Distributors

Tier 5: Processors & Fabricators

Accreditations

F4N Case Studies

KGD ENTERPRISES LIMITED

Other

Fabrication and Engineering -

Overview

KGD is a UK based Package Manufacturer with in-house Design, Manufacturing, Inspection, Painting & testing facilities working for UK & International Engineering & Oil multinationals on projects from £5K to over £15M. Our projects range from small works & repairs through to multimillion turnkey system builds where we carry out specialist structural fabrication, coded exotic pipe welding, NDT (RAD, PMI, Ferrite, DPI, MPI), blasting, painting & instrumentation / electrical services. Of particular relevance to this opportunity is our experience with cryogenic nitrogen generators and high pressure gas seal panels. We have also recently completed some packages as part of the Ichthys Project which included significant 100% XRay duplex pipework & exotic OD which was subject to extensive inspection. KGD has over 35 years experience, offering comprehensive services of a one stop shop for package builds plus all of our capabilities individually. This offers real benefits in terms of cost and confidence in quality and consistency of the final product which is ideal for your opportunity

Products and Services

| Product | Sector |

|---|---|

| Fabrication Med-integrity Structures | Oil & Gas including LNG |

| Coatings Paints Protection Processes & Systems | Oil & Gas including LNG |

| Instrumentation control computers detectors transmitters monitors & panels | Oil & Gas including LNG |

| Tanks | Oil & Gas including LNG |

| Welding & Welding Systems | Oil & Gas including LNG |

| Welding & Welding Systems | Oil & Gas including LNG |

Shotblasting Chilled Iron Grit For Carbon Steel

Shotblasting Garnet For Stainless Steel

Thermal Spraying

NDT Radiography

NDT Ultrasonic Inspection

NDT Dye Penetrant

NDT Magnetic Particle

NDT Positive Material Identification

NDT Ferrite Checking

Pipe Stress Analysis

Structural Calculations

4m 200 Tonne Break Press in dedicated Stainless Steel Workshop

Site Facilities

Shop Floor

7810m2 Office 550m2 Fabrication 3500m2 Clean Fabrication 880m2 Clean Assembly 1440m2 Painting / Blasting 1440m2 Yard Ample

Welding & Cladding

| Capability | Swing | Length | Width | |

|---|---|---|---|---|

| Gas Tungsten Arc Welding (GTAW)Semi-Automatic | Min: | - | - | - |

| Max: | - | - | - | |

| Manual Metal Arc Welding (MMA) | Min: | - | - | - |

| Max: | - | - | - | |

| Metal Inert Gas Welding (MIG) | Min: | - | - | - |

| Max: | - | - | - | |

| Orbital & Planetary (GTAW & SAW) | Min: | - | - | - |

| Max: | - | - | - | |

| Submerged Arc Welding (SAW) | Min: | - | - | - |

| Max: | - | - | - |

Inspection / Testing

- Electrical

- Non destructive testing - Magnetic Partical

- Non destructive testing - Radiography

- Non destructive testing - Ultrasonic

- Pressure / Hydro Testing

- Proof Load Testing

Design

- CAD Design - 2D

- CAD Design - 3D

Recent Work

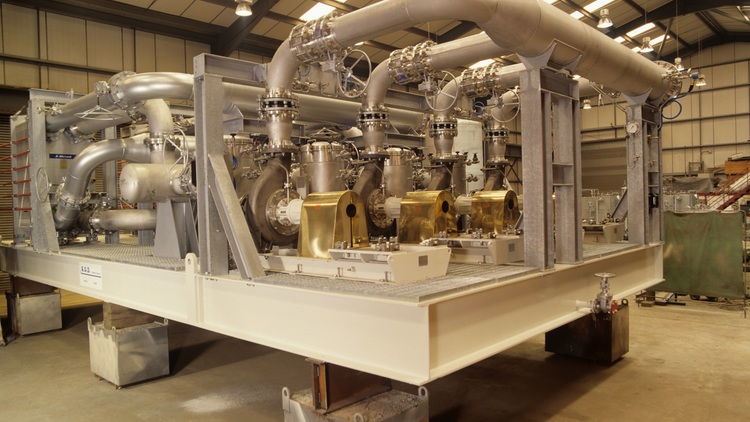

Electrochlorination System

Complete package build with stainless steel baseframe with titanium tank and pipework

Heat Exchanger Package

High pressure pipework sub arc welded

Chemical Injection skids

Complete package build using 625 instrument tubing

Pump and Heat Exchanger Package

80 Tonne package painted with NACE III inspection for 40 Year Design Life

MEG Treatment Package

• Structure BS EN 10225 S355 G11+M

• Vessels and pipework Duplex S31803

• Stringent material chemical & mechanical requirements

• Contract specific weld procedures with stringent heat input, chemical & mechanical testing.

• Clear lacquer on duplex & SS316L to protect during module build at ship yard

• 100% XRAY of duplex with acceptance standards better than ASME

• Segregation on all brackets, pipe support and dissimilar fixings.

• Human Factor Engineering applied to all valve & instrument location and access

• Electrical Equipment in Hazardous Areas (EEHA) installation and inspection

• Extended 40yr design life and 100 Yr storm conditions considered with FPSO to remain on station during typhoon.