-

Contact: Gareth Roberts

-

garethroberts@lestercast.co.uk

-

0116 276 7284

-

www.lestercast.co.uk

-

Investment Carting Centre

Ireton Avenue

Leicester

LE4 9EU

Leicestershire

- Size

- SME

- Direct employees

- 37

- Turnover (reported)

- £96,000,000

- Regional Markets

- Asia, Australia, Europe, North America

- Nuclear Contracting Tiers

- Tier 4: Sub-component Suppliers/Distributors

Tier 5: Processors & Fabricators

""

""

Accreditations

F4N Case Studies

Lestercast Ltd

Castings

Major UK manufacturer of precision investment castings, offering bespoke components in a range of metals including high temperature and specialist alloys, for both industrial and commercial applications, supplying to a diverse and global market. Castings are used in every sector and in many different manners.

Overview

Lestercast are an award-winning, major UK manufacturer of Precision Investment Castings, offering bespoke components in a range of metals and specialist alloys, for both industrial and commercial applications, supplying to diverse and global markets through various methods of advanced manufacturing technologies.

The supply of precision investment cast components or products in a variety of metals, alloys and other specialist material with additional treatments and finishes applied to meet individual customer specifications enables any design to be turned into a prototype and finished metal casting; specifically complex metal shapes that are impossible to make through other methods.

With the range of materials and processes available, we can offer flexibility and versatility in component design and production to ensure that specifications are achieved and products meet the highest possible quality standards.

Metals that can be cast within our facilities include but are not limited to:-

+ Non-Ferrous Metals

+ Ferrous Metals

+ Carbon Steels

+ Stainless Steels

+ Aluminium

+ Brass

+ Bronze

+ Copper

+ Zinc

+ Superalloys

+ Inconel

+ Hastelloy

+ Nickel

+ Low-Alloy Steels

Founded in 1972, Lestercast has grown significantly, investing regularly in all aspects of the business to diversify its reach.

The firm produces parts up to 20kg from it's investment casting centre in Leicester as well as high-volume parts of up to 150kg through a longstanding, successful partnership foundry in China.

With it's own in-house R&D centre capable of corrosion testing and further rapid prototyping facilities, Lestercast invests heavily in continually strengthening development in services such as additive manufacturing, 3D modelling, rapid prototyping, the full investment casting process, precision casting and beyond.

Service and Specialities Lestercast Offer:-

+ Robotic Linishing

+ Spectrometer

+ Corrosion Testing

+ High-resolution wax 3D Printers / Projet Printers - High quality castings without the need for tooling

+ Stockholding

+ Thin wall castings

+ High temperature alloys

+ Heat treatment

+ Hipping

+ Non-destructive testing, Crack Detection and X-ray

+ Tensile Testing & Charpy Testing

+ Machining / CNC Machining

+ Controlled traceability

+ Strict 100% inspection for all China-made parts

+ CMM

+ Milling

+ Grinding

+ Wire Eroding

+ Rapid low-volume production

+ Chemical Blacking

+ Polishing (Mirror or Satin)

+ Anodizing

+ Patination

+ Powder Coating

+ Plating

+ Electro-polishing

Already working into the Nuclear industry, the knowledge of the stringent protocol required for the Nuclear sector is fully understood and adhered to.

Lestercast is also working with Castings Technology International, one of the Nuclear AMRC's sister centres - to develop techniques to further develop techniques to improve the surface quality of complex castings by replacing the traditional wax pattern with an additively-manufactured resin form.

Products and Services

| Product | Sector |

|---|---|

| Materials Supplier - all forms | Nuclear Civil |

| Materials Forgings & Steels | Nuclear Civil |

| Materials Supplier - all forms | Nuclear Civil |

| Materials Forgings & Steels | Nuclear Civil |

| Modularised & Skid Mounted Process Systems | Nuclear Civil |

| Consumables | Nuclear Civil |

| Fire Protection Prevention Barriers Extinguishers & Systems | Nuclear Civil |

| Instrumentation control computers detectors transmitters monitors & panels | Nuclear Civil |

| Cranes Polar & Fuel Handling | Nuclear Civil |

| Alarms & Monitoring including Condition Monitoring | Nuclear Civil |

| Cable Supports Conduit Fixings Trays Trunking Ducting & Splicers | Nuclear Civil |

| Fasteners & Fixings including General & Hi-integrity | Nuclear Civil |

| Pumps including Main Reactor Circulation Pumps & Motors | Nuclear Civil |

| Tooling Equipment | Nuclear Civil |

| Valves including Main Isolation SQUIB & Actuators | Nuclear Civil |

| Pressure Vessels Heat Exchangers & Tanks including Internals | Nuclear Civil |

| Turbine Generators | Nuclear Civil |

| Detectors Sensors Transmitters & Detection Systems | Nuclear Civil |

| Detectors Sensors Transmitters & Detection Systems | Nuclear Civil |

| Fasteners & Fixings including General & Hi-integrity | Nuclear Civil |

| Filtration Systems Drums Screens Filters & Strainers | Nuclear Civil |

| Pumps including Main Reactor Circulation Pumps & Motors | Nuclear Civil |

| Valves including Main Isolation SQUIB & Actuators | Nuclear Civil |

Due to the diversity of our business and the bespoke requirements of our customers, we manufacture components for most sectors including:-

Automotive, Motorsport, Oil & Gas, Electrical, Marine, Construction, Rail, Transport, Utilities, Nuclear, Power, Safety Systems, Valve, Pumps, Flow Measurement, Electrical Equipment/Sensors, High Temperature Applications, Architectural, Bronzes/Jewellery, Environmental, Aerospace, Agricultural, Alternative Energy & Renewables, Nuclear, Power Generation, Construction, Petrochemical, Subsea & Offshore, Utilities.

Site Facilities

Shop Floor

7000m2 Lestercast has been quoted to have 'The cleanest and most well-organised, modern foundry I've ever had the pleasure to visit'. In order to facilitate an efficient and effective environment and continue to improve productivity, Lestercast has a unique and unrivalled strategy in developing and maintaining a clean, well organised and streamlined foundry. We have implemented Lean Manufacturing systems throughout and, as part of this, we continually inspect and audit our facilities to ensure we maintain high standards in our manufacturing process, produce excellent quality components and achieve on-time delivery for our customers. Considerable investment has been made in new equipment, machinery and rapid prototyping technologies to support the diverse and constantly changing needs of the industries we support. We have also implemented a programme of major enhancements to our premises, in order to provide a pleasant, modern working environment for all of our employees, and to offer excellent on-site training and conferencing facilities. We are particularly proud of our facility and would encourage and welcome existing and prospective clients to visit us for a tour, refreshments and a chat!

Inspection / Testing

- Clean room facilities

- CMM machines

- Non destructive testing - Magnetic Partical

- Non destructive testing - Radiography

- Non destructive testing - Ultrasonic

- Pressure / Hydro Testing

- Proof Load Testing

- Temperature controlled facility for inspection

Design

- CAD Design - 2D

- CAD Design - 3D

Recent Work

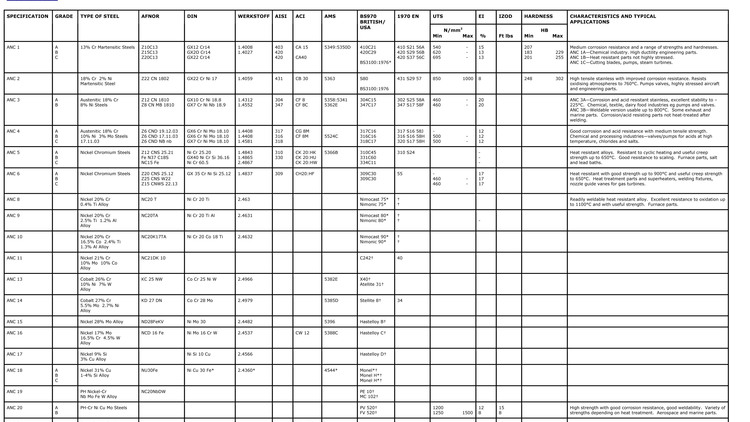

Ferrous Metals - Alloy Steels, Nickel and Cobalt Alloys

Please find below the images of the breakdown of metals and alloys we offer in our casting procedures, we would be keen to discuss any other materials required. These tables are intended as a guide only, the full relevant standard specifications should be referred to when determining suitable materials for a particular product and its application.

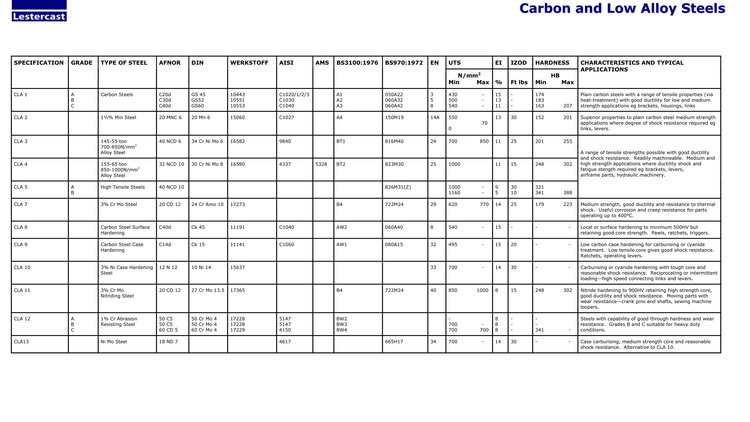

Ferrous Metals - Aluminium Alloys, Zinc and Copper Based Alloys

Please find below the images of the breakdown of metals and alloys we offer in our casting procedures, we would be keen to discuss any other materials required. These tables are intended as a guide only, the full relevant standard specifications should be referred to when determining suitable materials for a particular product and its application.

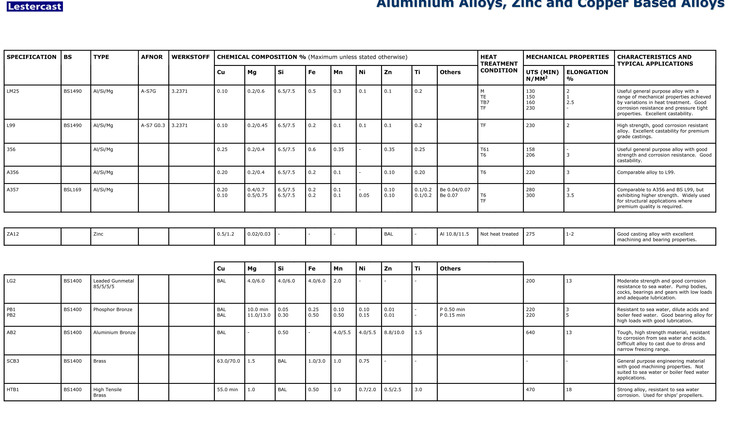

Non-Ferrous Metals - Aluminium Alloys, Zinc and Copper Based Alloys

Please find below the images of the breakdown of metals and alloys we offer in our casting procedures, we would be keen to discuss any other materials required. These tables are intended as a guide only, the full relevant standard specifications should be referred to when determining suitable materials for a particular product and its application.

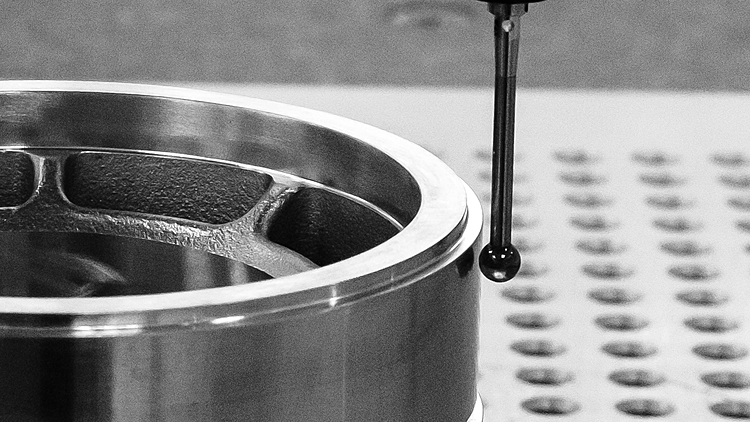

CMM Machine

Inspection processes using the CMM machine to finely assess dimensions of castings

The Casting Process

Dewaxing - once the ceramic is dry following the investing process, the wax is melted out in an autoclave creating a negative impression of the assembly within the shell. The shell mould is then fired in a high temperature oven.

Wax replicas

Wax replicas of the desired casting are produced by injection moulding using a metal die. These replicas are called patterns.