-

Contact: SHAUN STEVENSON

-

sstevenson@sl-engineering.co.uk

-

07940 533317

-

www.sl-engineering.co.uk

-

Temple Road

Aslackby

Sleaford

NG34 0HJ

Lincolnshire

- Size

- SME

- Direct employees

- 51

- Turnover (reported)

- £6,000,000

- Regional Markets

- Asia, Europe, North America

- Nuclear Contracting Tiers

- Tier 3: Original Equipment Manufacturing Organisations

Tier 4: Sub-component Suppliers/Distributors

Tier 5: Processors & Fabricators

Accreditations

SL Engineering Ltd

Pipework Systems & Seals

Overview

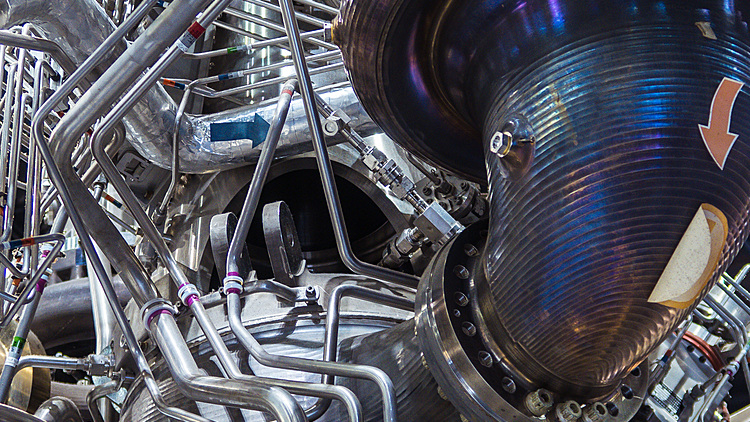

SL Engineering provides full in-house solution based manufacture of specialised rigid tube assemblies, fabricated & welded pipes, complex tubular manifolds, ducting, conduits, flexi-rigid metallic hose assemblies, & CNC precision machined pipe fittings used in some of the world’s most demanding & critical fluid conveyance applications.

Established in 1959, with over 60 years’ experience, modern facilities & state of the art CNC plant & equipment employing CAD/CAM systems, we have an internationally recognised reputation for producing very competitively priced exceptional quality products, supplied globally to our major OEM customers in the UK, Europe, North America, & Asia.

In-house capabilities include CNC tube manipulation (up to 76.2mm [3.0”] diameters), CMM contact & non-contact laser tube inspection, CNC multi-axis turn-mill precision machining including full 5 axis capability (for the manufacture of bespoke machined tubes & pipe end fittings), computerised orbital & hand tig welding, torch & induction brazing, pipe fabrication, swaging & assembly, NDT dye penetrant & x-ray testing, air, hydraulic & nitrogen gas pressure testing, enabling us to provide a complete in house solution.

SL are an ambitious high performing organisation with a strategic growth mission to “double in 5” years, & following a rigorous assessment process were selected as a beneficiary on the prestigious Sharing in Growth (SIG) program to support our journey to deliver continuous business improvement & process excellence.

Products and Services

| Product | Sector |

|---|---|

| Materials Tubing & Pipework | Power Generation, Distribution & Transmission |

| Materials Tubing & Pipework | Aerospace - Civil and Defence |

| Pipework Systems including Seals | Nuclear Defence - Naval Marine |

| Pipework Systems including Seals | Aerospace - Civil and Defence |

| Pipework Fittings & Spools | Nuclear Defence - Naval Marine |

| Pipework Fittings & Spools | Aerospace - Civil and Defence |

| Ducting | Aerospace - Civil and Defence |

| Precision & General Machining | Power Generation, Distribution & Transmission |

| Precision & General Machining | Aerospace - Civil and Defence |

Manipulated rigid tube assemblies, fabricated & welded pipes, complex tubular manifolds, ducting, conduits, flexi-rigid metallic hose assemblies, pressure testing, NDT dye-penetrant & radiographic testing, & CNC precision machined pipe fittings

Site Facilities

Shop Floor

1672m2 SL Engineering's products are manufactured in 4 operational business units; CNC tube manipulation & forming, CNC multi-axis precision machining, pipe assembly, welding & fabrication, & NDT & inspection.

Specialist Machinery

| Capability | Swing | Length | Width | Weight | |

|---|---|---|---|---|---|

| 4 Axis Milling | Min: | - | - | - | N/A |

| Max: | - | - | - | - | |

| 5 Axis Milling | Min: | - | - | - | N/A |

| Max: | - | - | - | - | |

| Vertical Milling (CNC ) | Min: | - | - | - | N/A |

| Max: | - | - | - | - | |

| Vertical Mill / Turn | Min: | - | - | - | N/A |

| Max: | - | - | - | - |

Welding & Cladding

| Capability | Swing | Length | Width | |

|---|---|---|---|---|

| Gas Tungsten Arc Welding (GTAW) | Min: | - | - | - |

| Max: | - | - | - | |

| Metal Inert Gas Welding (MIG) | Min: | - | - | - |

| Max: | - | - | - | |

| Orbital & Planetary (GTAW & SAW) | Min: | - | - | - |

| Max: | - | - | - |

Inspection / Testing

- CMM machines

- Non destructive testing - Radiography

- Temperature controlled facility for inspection

Design

- CAM Design - 2D

- CAM Design - 3D

Recent Work

SL Engineering Pipe & Tube Assemblies

Examples of the type of pipe & tube assemblies manufactured at SL Engineering Ltd for the Power Generation Industry

CNC Tube Manipulation

CNC pipe bending is carried out by SL Engineering Ltd using state of the art all-electric tube bending machines

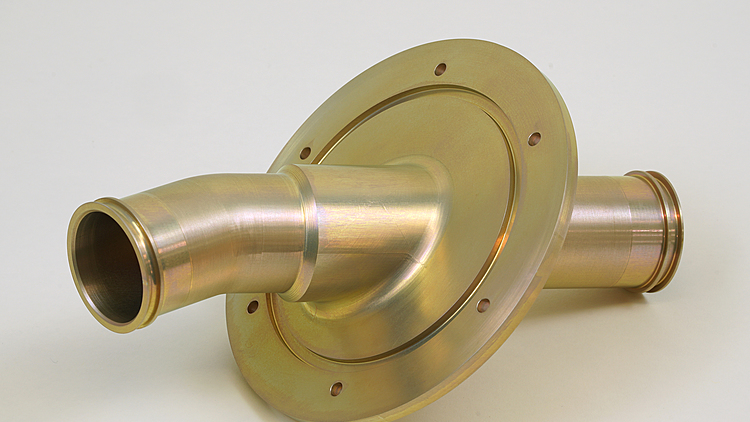

CNC Precision Machining

The production of pipe & tube end fittings is carried out using multi-axis turn-mill & full 5 axis machining to produce simple turned to highly complex 5 axis prismatic port machined pipe units from solid bar.

Welded Pipe Assemblies

Full high integrity hand tig, computerised orbital tig, & brazing of pipe assemblies are carried out in house.