-

Contact: Chris Truman

-

chris.truman@syspal.com

-

01952 885121

-

https://manifab.com/

-

Cockshut Lane

Broseley

Tf12 5ja

Shropshire

- Size

- SME

- Direct employees

- 165

- Turnover (reported)

- £20,000,000

- Regional Markets

- Asia, Africa, Australia, Europe, North America, South America

- Nuclear Contracting Tiers

- Tier 3: Original Equipment Manufacturing Organisations

Tier 4: Sub-component Suppliers/Distributors

Tier 5: Processors & Fabricators

Accreditations

Syspal Ltd

Steel Fabrications

Stainless Steel and Aluminium precision fabrications

Overview

MANiFAB a division of SYSPAL Ltd is based in Shropshire working from an 11,500 sq mtr manufacturing facility close to the historic Iron Bridge was established in 1975 and currently employees 200 people.

Specialists in high quality, high performance stainless steel and aluminium fabricated products primarily to the food processing, bio pharma, veterinary, medical, architectural, military, nuclear and sub contract sectors. We are open to sharing our best practice processes with partners in the nuclear industry.

Typical applications include:

- Conveyors

- Lifting equipment

- Goods elevators

- Bulk material handling

- Fabrication of specialist projects

- Access equipment

- Manual and mechanical handling equipment

One of the most technically advanced manufacturing facilities in Europe. Capabilities include:

- 3D design and product evaluation supported by, FEA and manufacturing simulation

- Control systems

- User interfaces and software development

On site fabrication equipment includes;

- Sheet and tube laser cutting

- Sheet metal forming with ToolCells

- MiG & TiG welding by coded welders

- Automated seam welding (TiG)

- Bead blasting

- Finishing

- Assembly and testing

We invite partners looking to design and develop products using the latest digital techniques (i4) and efficient processes to provide outstanding results.

CAPABILITIES INCLUDE:

Automated material storage systems

• Sheet (4m x 2m)

• Sections (6m)

• Small parts

• Vacuum sheet handling system

Pre Production - Off line programming

• Sheet lasers

• Tube laser

• Sheet metal forming

Sheet laser cutting

• 4 kw 4m x 2m – 15mm thick stainless steel 10mm thick aluminium

• 15 kw 4m x 2m - 20mm thick stainless steel 20mm thick aluminium

Tube laser cutting

• 3 kw 15 - 150mm dia x 6m capability with auto feed

Saws

• Circular saws - automated feed

• Band saw - automated feed -

Tube manipulation

• Mandrel and push bending 15 – 75mm dia.

• Laser measuring.

Dee burring

• Time saver sheet de burring machine > 1300mm

• Vibratory de burring

• Thick part de burring

Sheet metal forming

• ToolCell 4m x 220 t - automated tool loading - laser measuring

• ToolCel 3m x 220 t Plus - automated tool loading - laser measuring

• 4m x 320 t hydraulic press brake – increased daylight – hydraulic tool clamping – tool storage magazine

Finishing

• 3m belt linishing machines x 2

• Stainless steel shot blasting booth >6m

Welding

• Seam welding booms x 2

• Manual welding TiG & MiG x 30 stations

Sheet rolling

• >3mm thk > 1.5m lg

Mechanical/ electrical

• Assembly and testing

Products and Services

| Product | Sector |

|---|---|

| Fabrication Med-integrity Structures | Nuclear Civil |

| Fabrication Hi-integrity & Complex Structures including Heavy | Nuclear Civil |

| Steelwork including Mezzanine & Gantry Systems | Construction - Strategic Platforms & Vessels |

| Mechanical Handling & Cranes | Nuclear Civil |

| Tanks | Construction - Strategic Platforms & Vessels |

| Welding & Welding Systems | Nuclear Civil |

| Welding & Welding Systems | Nuclear Civil |

Site Facilities

Shop Floor

11500m2

Inspection / Testing

- Advanced testing facilities

Design

- CAD Design - 2D

- CAD Design - 3D

- CAM Design - 2D

- CAM Design - 3D

Recent Work

Mechanical Handling Project

Food processing project incorporating double column tippers, vibratory conveyors, high speed tippers and a gantry access system. Designed to meet the production requirements of a customer to ensure increased efficiency and reduced manual handling.

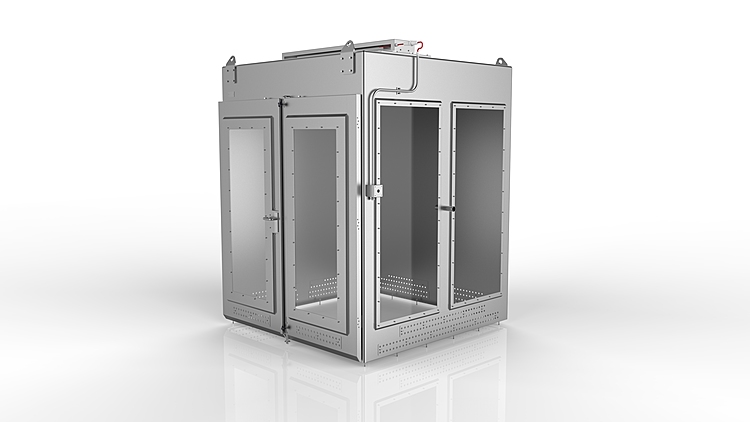

Degassing Chamber

Degassing chamber constructed from stainless steel. Designed following a client brief using the latest industry 4.0 manufacturing techniques.